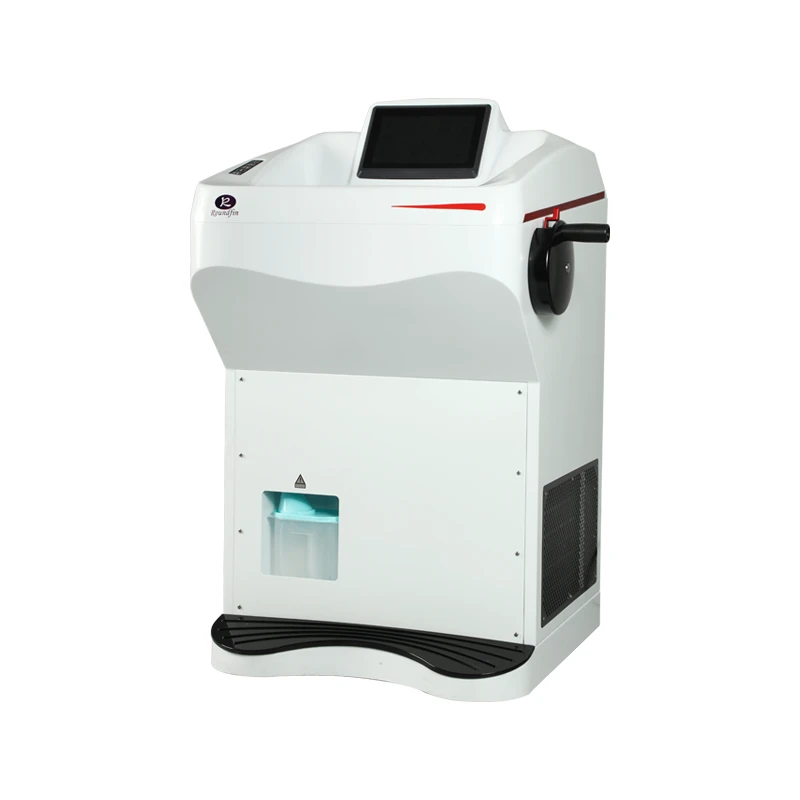

Roundfin RD-500 Carousel Type Auto Tissue Processor

- Roundfin

- China

- 15 days

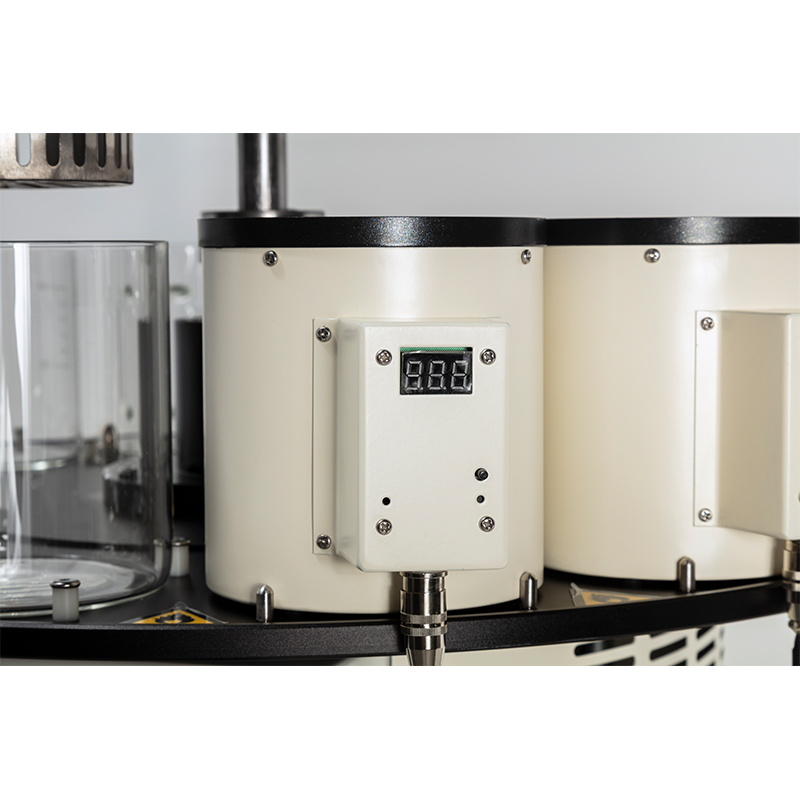

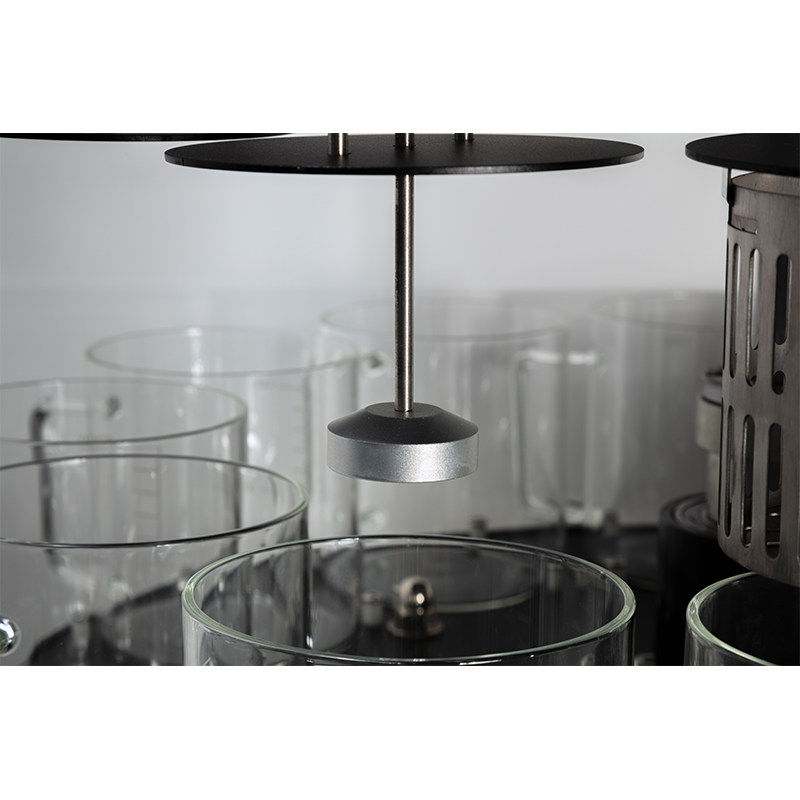

1. Sample basket rotates for thorough mixing.

2. Transparent reagent cylinder aids in replacement and monitoring.

3. Dual limiters prevent equipment damage.

4. Obstacle sensor prevents mishaps.

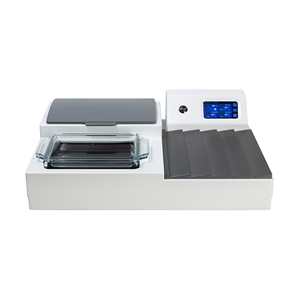

5. Pause during cylinder replacement prevents spills.

6. 10 programming options for versatility

Roundfin RD-500 Auto Tissue Processor

Specification

| RD-500 Auto Tissue Processor | |||

| Number of reagent cups: | 12 - Reagent cups: 9 Paraffin cups: 3 | ||

| Volume | Paraffin cup capacity | Number of cassettes | |

| 1.3L Single basket | 1L | 50 | |

| Reagent cup volume (optional configuration) | 1.3L Double basket | 100 | |

| 2.3L Single basket | 2L | 100 | |

| 2.3L Double basket | 200 | ||

| Paraffin cup temperature range | 0-85℃ | ||

| Reagent cup work time setting range | 0-2000min | ||

| Draining time: | 30s | ||

| Frequency of basket stirring | 5min/time 1min once | ||

| Operating temperature/humidity | Working temperature: Rt--70℃ | ||

| Operating temperature 15℃--40℃ | |||

| Humidity 20-80% non-condensing | |||

| Product Size | Φ660*(600-720)/φ780*(600-720)mm | ||

| Weight | 65KG/75KG | ||

| Voltage | 220V 50Hz /110V 60Hz | ||

| Power | 300W | ||

| Wax heating power: 80w/pc | |||

| Basket rotation power: 4w/pc | |||

| Lifting motor power: 25w | |||

| Rotation motor power: 14w | |||

| Fuse | Φ5*20mm,10A AC 120V | ||

| Other | |||

| Certification | CE; ISO; 13485 | ||

| Brand | ROUNDFIN - Accept OEM | ||

| Warranty | 2 years, lifetime technical support | ||

| Customize needes | According to communication | ||

| Packing size / weight | 115KG 105*80*78CM | ||

| 140KG 120*90*79CM | |||

Feature

1. The sample basket has a built-in rotation function, rotating every five minutes to ensure thorough mixing of the sample with reagents, resulting in more complete reactions. 2. The reagent cylinder is made of transparent glass with handles, facilitating the retrieval and replacement of reagents. It also provides visualization of the specimen's status during dehydration. 3. The equipment is equipped with two limiters: internal software limits and external mechanical limiters, preventing dangerous component damage in case of malfunctions. 4. The equipment features an obstacle detection sensor that promptly stops operation upon encountering obstacles, preventing damage to experiments and the machine itself caused by unmelted paraffin or other foreign objects. 5. When replacing the reagent cylinder, the equipment pauses for 5 seconds at the top to allow excess liquid to drip off, preventing reagent spillage. 6. It comes with 10 built-in programming options, offering users more choices. 7. The equipment includes a power-off protection system that resumes operation from the memory position upon power restoration. 8. Users can switch between manual and automatic modes according to their needs. 9. Users can set a delayed start time, with the option to delay up to 30 days, to accommodate specific scheduling requirements.