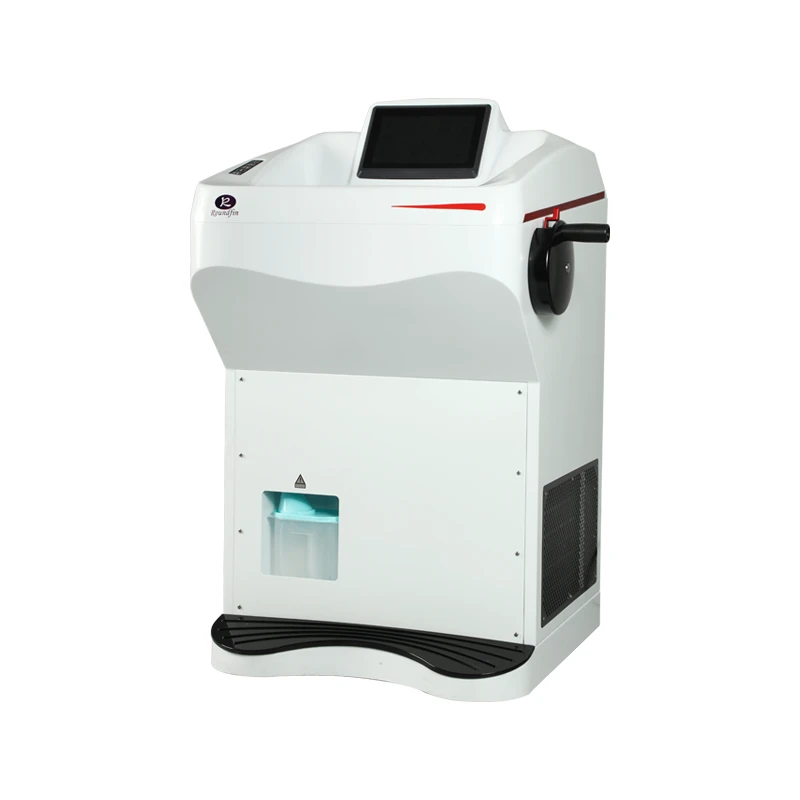

Roundfin RD-355ATK Automatic Microtome

- Roundfin

- China

- 10-15 days

1. This machine uses a streamlined design, with advanced features, stable and reliable performance and ease of use

2. The feeding system uses an intelligent control mechanism; enabling quick switching between manual or automated smart sectioning modes; automatic slicing speed is adjustable

3. Advanced drive systems and multiple functions including sectioning, trimming, fast forward, fast backward, quick mode conversion including automatic retraction

4. Incorporates an international advanced screw motion mechanism to ensure precision, thus achieving superior sectioning performance

Roundfin RD-355ATK Automatic Microtome

Features

This machine uses a streamlined design, with advanced features, stable and reliable performance and ease of use

The feeding system uses an intelligent control mechanism; enabling quick switching between manual or automated smart sectioning modes; automatic slicing speed is adjustable

Advanced drive systems and multiple functions including sectioning, trimming, fast forward, fast backward, quick mode conversion including automatic retraction

Incorporates an international advanced screw motion mechanism to ensure precision, thus achieving superior sectioning performance

Pure-green digital display of slice thickness, trimming thickness, slice count and slice speed

Trimming and slicing are operated under a control system, and can be switched easily. The automated slicing controller can be equipped at either the left or right side; when automated slicing controller is off, semi-auto slicing or trimming can still be performed

Automatic sectioning speed is continuously adjustable

With safety and emergency braking systems, security alarm systems, driver overload protection and an auto-sleep protection system

Features easy and fast switching between different specimen clamps (two options: paraffin block clamp and cassette clamp)

Hand-wheel balance is precisely adjusted and can be locked at any position to ensure safety of operation

Blade holder can be laterally moved to avoid moving the blade with direct contact, thereby enabling use of the entire length of the blade. (three different segments)

The red protection bar on the blade holder covers the whole length of blade to protect the user and the push bar enables easy changing of the blade

Hand-wheel balance is precisely adjusted and can be locked at any position to ensure the safety and convenience of sectioning

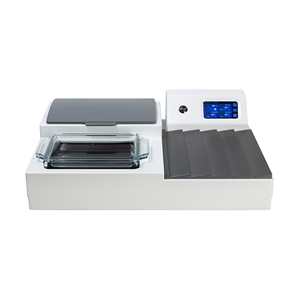

Large-volume waste tray is easy to remove, and items such as deposable blades can be stored on the top of the housing

Technical Specifications

§ Section Thickness Setting Range: 0.25—100μm

0.25—2.5μm increment 0.25μm

2.5—5μm increment 0.5μm

5.0—10μm increment 1μm

10—30μm increment 2μm

30—60μm increment 5μm

60—100μm increment 10μm

§ Trimming Thickness Setting Range: 1—600μm

1—10μm increment 1μm

10—20μm increment 2μm

20—50μm increment 5μm

50—150μm increment 10μm

150—600μm increment 50μm

§ Retraction Setting Range: 0—50μm ( 0 is off )

5-10-15—50 (optional)

§ Minimum Setting of Sectioning Thickness: 0.25μm

§ Horizontal Feed: 28mm

§ Vertical Specimen Stroke: 70mm

§ Specimen Holder Rotation: at any angle within 360 degrees

§ Movement Range of the Base of Blade Holder Base: 0-60mm (front to back)

§ Movement Range of the Blade Press plate: 0-23mm

§ Specimen Clamp Rotation: at any angle within 360 degrees

§ Specimen Orientation: XY – 8°

§ Maximum Specimen Size:70×70mm (optional clamp)

§ Feed speed adjust: 1500μm/s ~ 3500μm/s

§ Precision Error: ±1%

§ Working Voltage: AC 220V±10% 50Hz (standard model); AC110V±10% 60Hz

§ Power: 150W

§ Dimensions: 580× 475× 340mm(W×D×H)

§ Net Weight: 41kg